Workflow

- Design your part in CAD software (e.g., Fusion 360, FreeCAD, or SolidWorks).

- Create toolpaths in CAM software (e.g., Fusion 360 CAM, VCarve, EstlCAM).

- Export G-code for the Stepcraft controller.

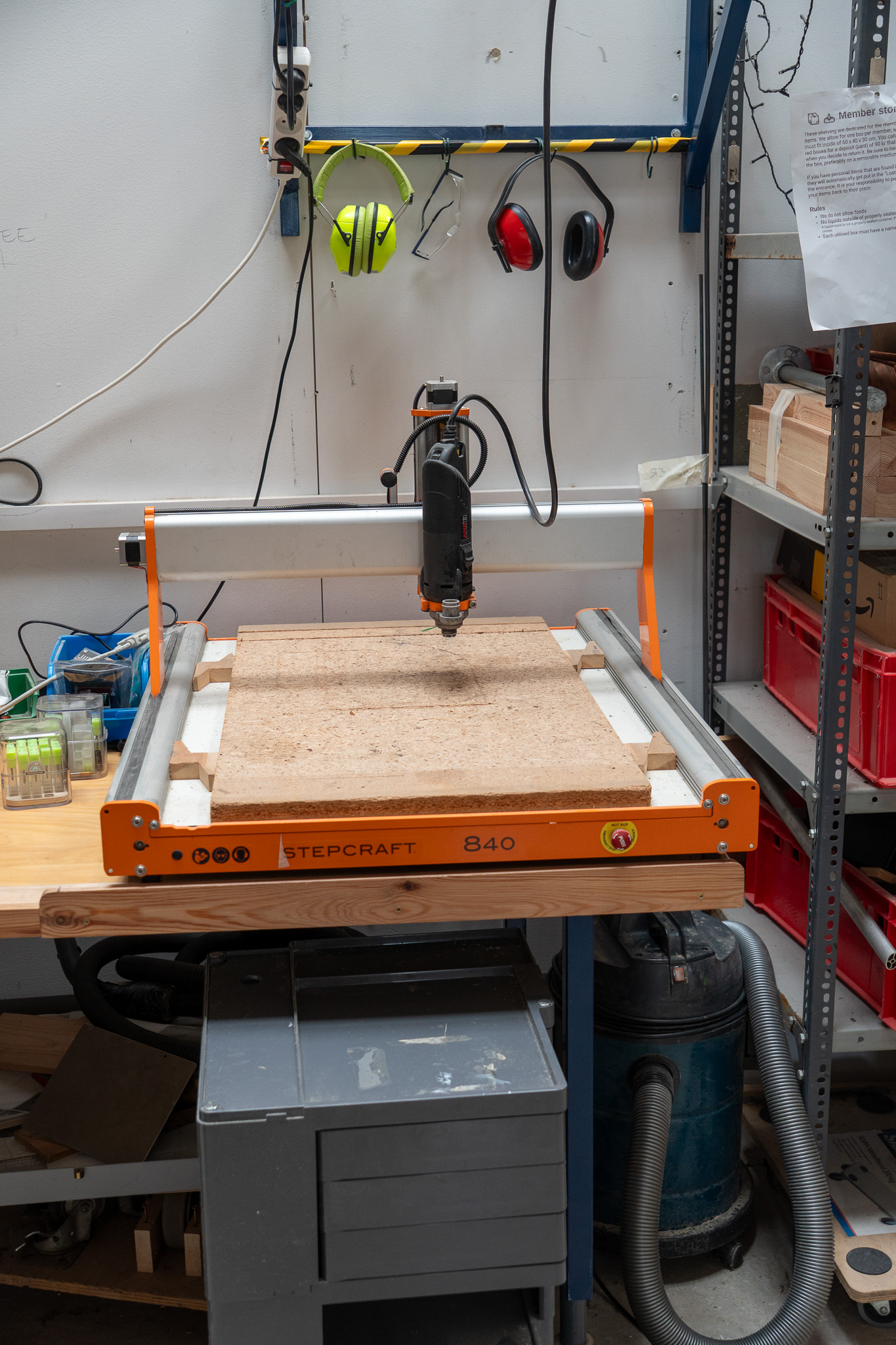

- Secure your material on the CNC bed with screws. Make sure that screws do not go through sacrificial fiber-wood board.

- Install the correct bit, set zero points, and check clearance.

- Run a simulation and test cut before full operation.

Safety & Best Practices

- Always wear safety glasses and ear protection.

- Make sure material is clamped firmly to avoid shifting.

- Stand clear of the spindle path during operation.

- Never leave the machine unattended while running.

- Clean chips and dust after each session using the vacuum system.

Additional Tools & Equipment

- Collets and bit set (end mills, V-bits, ball nose, etc.)

- Calipers for measurement

- Hold-down fixtures with screws and glue tape

- Vacuum cleaner

- Spray bottle for lubricating while cutting metals

Getting Started

New members must complete an introduction to the CNC machine before use. This training covers CAD/CAM basics, machine setup, tool changing, and safety procedures.